KRONE KWT 1300 Trailed Rotary Tedder

KRONE KWT 1300 Trailed Rotary Tedder

The KRONE KWT 1300 is the tedder for supreme quality forage. Pleasant to operate,

the machine teds 13.10 m in one operation. Highly productive, it is yet gentle on the crop and soil but compact and safe in road travel.

Key features:

- Huge 13.10 m work width.

- 12 rotors with 6 tine arms each.

- Drawbar or three-point linkage attachment.

- Automated transport/work changeovers.

- Flexible rotor guidance, exact ground contouring.

- KWT 1300 is available in many different attachment systems. The standard attachment is a drawbar with with 40 mm hitch ring for top and bottom attachment. An 80 hitch ball or a pivoting drawbar is an option.

- The bottom arms on the chassis give very accurate guidance of the rotors. The wheels on the transport running gear are simply castering, serving as a leading gauge wheel for active tine contouring control.

- The hydraulic top link is in float position during work providing optimum ground contour following and maintaining the set work height. On the headland and changing in transport position, the link raises the entire frame into an approx. 90° position.

- The flexible tubes ensure the material is adequately tedded even across the full work width and in undulating fields. Permanently lubricated rotor gearboxes, robust 9.5 mm double tines of unequal lengths, robust tube-section tine holders, a sturdy frame with individual segment adjustment and a wide transport chassis running on flotation tyres - all this combines to cope with highest loads and deliver excellent results on and on.

- Featuring maintenance-free eight-finger clutch and rotor gearboxes that are immersed in semi-fluid grease, the KWT 1300 models are made to cope with the highest loads and continue delivering during a long life.

- The 1.53 m diameter rotors with six tine arms and robust double tines of unequal lengths produce an exemplary spread pattern.

- High-strength beams are made to cope with the strains of a huge work width. The enclosed hoop guard features cross braces that are arranged at an angle for extra stability. The heavy-duty build not only complies with safety standards but also takes off load from the side arms and joints.

- The coil spring connects the top link coupler with the transport frame. When the rotors are in headland position the spring is pressing on the frame, compensating for negative tongue load. This detail allows you to operate a KWT 1300 with a smaller or more lightweight tractor.

- The height of all tines is altered on this crank in the middle of the machine for quick and easy adjustment to varying conditions.

- The curtain is controlled hydraulically and is an option for those who seek maximum precision in border spreading. The crop is not thrown beyond the field border.

- Both the KWT 1300 fold automatically and sequence controlled from the cab thereby eliminating any risk of operator error. As a last step, a separate spool raises / lowers the booms into headland / work position.

- The wide transport running gear ensures quiet running and good road stability even on rough roads. Wider tyres are an option here, because flotation rubber on the transport chassis translates into softer treading in boggy terrain and reduced soil compaction thanks to a large contact area.

Specification for KRONE KWT 1300 Trailed Rotary Tedder

Trailed

13.1m

12

70hp

6

1.53m

2750kg

This product has no reviews.

Leave a Review

This product has no questions.

Ask a Question

-

Description

The KRONE KWT 1300 is the tedder for supreme quality forage. Pleasant to operate,

the machine teds 13.10 m in one operation. Highly productive, it is yet gentle on the crop and soil but compact and safe in road travel.Key features:

- Huge 13.10 m work width.

- 12 rotors with 6 tine arms each.

- Drawbar or three-point linkage attachment.

- Automated transport/work changeovers.

- Flexible rotor guidance, exact ground contouring.

- KWT 1300 is available in many different attachment systems. The standard attachment is a drawbar with with 40 mm hitch ring for top and bottom attachment. An 80 hitch ball or a pivoting drawbar is an option.

- The bottom arms on the chassis give very accurate guidance of the rotors. The wheels on the transport running gear are simply castering, serving as a leading gauge wheel for active tine contouring control.

- The hydraulic top link is in float position during work providing optimum ground contour following and maintaining the set work height. On the headland and changing in transport position, the link raises the entire frame into an approx. 90° position.

- The flexible tubes ensure the material is adequately tedded even across the full work width and in undulating fields. Permanently lubricated rotor gearboxes, robust 9.5 mm double tines of unequal lengths, robust tube-section tine holders, a sturdy frame with individual segment adjustment and a wide transport chassis running on flotation tyres - all this combines to cope with highest loads and deliver excellent results on and on.

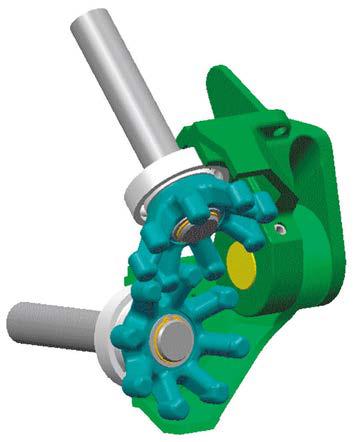

- Featuring maintenance-free eight-finger clutch and rotor gearboxes that are immersed in semi-fluid grease, the KWT 1300 models are made to cope with the highest loads and continue delivering during a long life.

- The 1.53 m diameter rotors with six tine arms and robust double tines of unequal lengths produce an exemplary spread pattern.

- High-strength beams are made to cope with the strains of a huge work width. The enclosed hoop guard features cross braces that are arranged at an angle for extra stability. The heavy-duty build not only complies with safety standards but also takes off load from the side arms and joints.

- The coil spring connects the top link coupler with the transport frame. When the rotors are in headland position the spring is pressing on the frame, compensating for negative tongue load. This detail allows you to operate a KWT 1300 with a smaller or more lightweight tractor.

- The height of all tines is altered on this crank in the middle of the machine for quick and easy adjustment to varying conditions.

- The curtain is controlled hydraulically and is an option for those who seek maximum precision in border spreading. The crop is not thrown beyond the field border.

- Both the KWT 1300 fold automatically and sequence controlled from the cab thereby eliminating any risk of operator error. As a last step, a separate spool raises / lowers the booms into headland / work position.

- The wide transport running gear ensures quiet running and good road stability even on rough roads. Wider tyres are an option here, because flotation rubber on the transport chassis translates into softer treading in boggy terrain and reduced soil compaction thanks to a large contact area.

-

Specifications

Trailed 13.1m 12 70hp 6 1.53m 2750kg -

Reviews

This product has no reviews.Leave a Review

-

Q&A's

This product has no questions.Ask a Question

-

Attachments

-

Images

-

Videos