PÖTTINGER NOVACAT A10 Mower Combinations with Centre Pivot Suspension

PÖTTINGER NOVACAT A10 Mower Combinations with Centre Pivot Suspension

The NOVACAT A10 mower combination is a front/rear combination with a special cutting width optimisation system. This enables flexible width adjustment to differing operating conditions. The cutting width and mower unit overlap can be optimised on the move for working on slopes, while cornering and on flat areas.

The high level of user convenience, ingenious details, a wide range of applications, strength and first-class cutting quality make these mower combinations among the most productive in their class.

Key features:

- NOVACAT A9 with swath formers.

- A10 Reliability and durability, reliable operation in all situations.

- A10 mounting available as an option. Two main frames are available for use in combination with either a 3 or 3.5 metre wide front mower. The centre-to-centre spacing of the two mower units is 1.88 – 2.64 m or 2.34 – 3.10 m.

- NONSTOP LIFT hydraulic collision safety device protects the mower. NONSTOP LIFT is an innovative technology that offers the best protection to the cutter bar. Fitted to both sides, the collision safety device enables the cutter bar to avoid obstacles efficiently. When triggered, the boom folds backwards on the triangular frame and is simultaneously raised at the front by the gimbal - a three-dimensional collision safety system. The mower avoids impact with the obstruction so that damage to the cutter bar is prevented even at higher driving speeds.

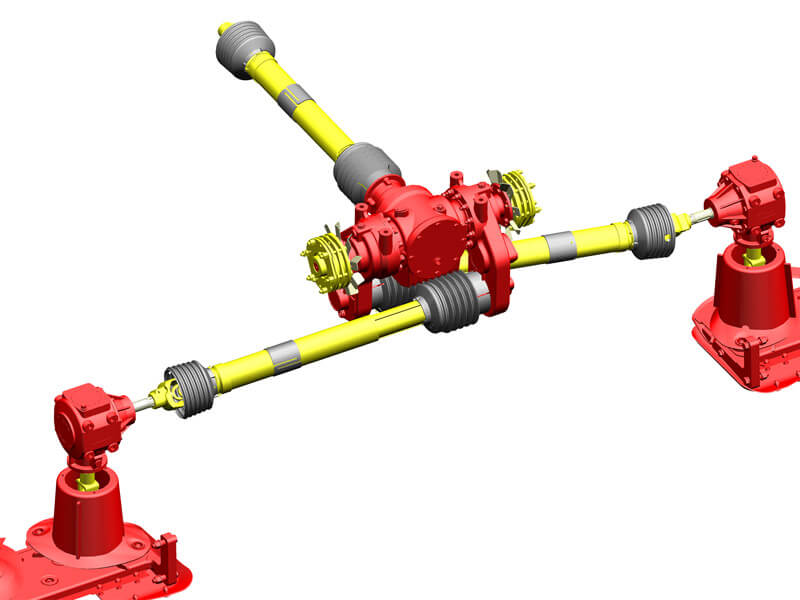

- Extended service life thanks to Y DRIVE. New generation driveline. The special Y DRIVE input gearbox utilises bevel cut gears and presents the mower drive shaft on the opposing side to the mower. This has the advantage that longer standard PTO shafts can be used with less of an angle in operation.

- The backlash-free driveline using standard driveshafts has been made possible by locating the slip clutch and freewheel directly at the gearbox. Integrated fan blades cool the gearbox in operation.

- As a result, the driveline offers exceptionally smooth operation even when raised at the headland or in the heaviest of crop conditions. This new design extends service life significantly.

- Consistent power transmission. A constant velocity joint in the inside mower drum provides a stress-free link between the angular gearbox and the cutter bar. The gears are submerged in gear oil.

- Robust technology - long service life The heavy-duty boom design offers a wide bearing spacing, which carries the cutter bar and provides the optimum in support.

- The cutter bar is mounted from both ends which protects it against twisting. As a result, the cutter bar gears and bearings are subjected to less stress for smoother operation and a long service life.

Specification for PÖTTINGER NOVACAT A10 Mower Combinations with Centre Pivot Suspension

Leave a Review

Ask a Question

-

Description

The NOVACAT A10 mower combination is a front/rear combination with a special cutting width optimisation system. This enables flexible width adjustment to differing operating conditions. The cutting width and mower unit overlap can be optimised on the move for working on slopes, while cornering and on flat areas.

The high level of user convenience, ingenious details, a wide range of applications, strength and first-class cutting quality make these mower combinations among the most productive in their class.

Key features:

- NOVACAT A9 with swath formers.

- A10 Reliability and durability, reliable operation in all situations.

- A10 mounting available as an option. Two main frames are available for use in combination with either a 3 or 3.5 metre wide front mower. The centre-to-centre spacing of the two mower units is 1.88 – 2.64 m or 2.34 – 3.10 m.

- NONSTOP LIFT hydraulic collision safety device protects the mower. NONSTOP LIFT is an innovative technology that offers the best protection to the cutter bar. Fitted to both sides, the collision safety device enables the cutter bar to avoid obstacles efficiently. When triggered, the boom folds backwards on the triangular frame and is simultaneously raised at the front by the gimbal - a three-dimensional collision safety system. The mower avoids impact with the obstruction so that damage to the cutter bar is prevented even at higher driving speeds.

- Extended service life thanks to Y DRIVE. New generation driveline. The special Y DRIVE input gearbox utilises bevel cut gears and presents the mower drive shaft on the opposing side to the mower. This has the advantage that longer standard PTO shafts can be used with less of an angle in operation.

- The backlash-free driveline using standard driveshafts has been made possible by locating the slip clutch and freewheel directly at the gearbox. Integrated fan blades cool the gearbox in operation.

- As a result, the driveline offers exceptionally smooth operation even when raised at the headland or in the heaviest of crop conditions. This new design extends service life significantly.

- Consistent power transmission. A constant velocity joint in the inside mower drum provides a stress-free link between the angular gearbox and the cutter bar. The gears are submerged in gear oil.

- Robust technology - long service life The heavy-duty boom design offers a wide bearing spacing, which carries the cutter bar and provides the optimum in support.

- The cutter bar is mounted from both ends which protects it against twisting. As a result, the cutter bar gears and bearings are subjected to less stress for smoother operation and a long service life.

-

Specifications

Combination 8.8m - 10.02m 3.99m 3.15m 160hp 1000rpm 32 2350kg 16 -

Reviews

This product has no reviews.Leave a Review

-

Q&A's

This product has no questions.Ask a Question

-

Attachments

-

Images