KEENAN VA 2- 30

KEENAN VA 2- 30

The KEENAN VA2-30 Diet Feeder is a heavy-duty machine with the capacity to feed large herds quickly. Multiple feed-out options to suit a variety of feeding situations are available with this machine. This applies to the full range of the KEENAN VA machines.

Key Features

- Discharge: Front right hand side and rear left and side discharge with trays for dual feedout

- Speed: Engineered to optimise use of space, by allowing materials to be rapidly and efficiently mixed into the overall mixed ration.

- Capacity: The efficient use of space means that this machine may load and mix the full volumes of material consistent with their declared capacity.

- Heavy Duty Auger and Blades: Fitted with a heavy duty auger as standard. The triangular blades are fitted with a long lasting tungsten coating which increases their longevity. The additional two blades are fitted towards the top of each auger ensuring rapid incorporation of bales.

- Inspection platform: Fitted as standard this machine offers an inspection platform for viewing the mix.

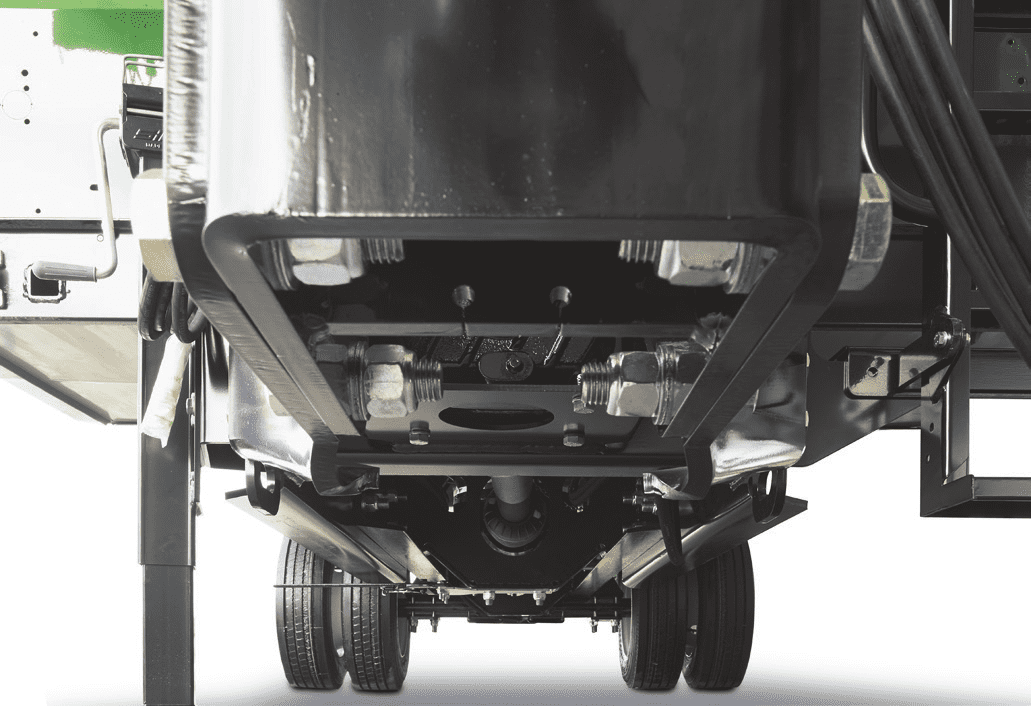

- Heavy Duty Chassis: This machine is mounted on a custom-built heavy duty chassis. Its robust construction ensures durability and reliability even under the toughest conditions.

- Hay Ring: This machine is fitted with a hay ring to prevent overflow of material.

- Footprint and Handling: This machines footprint is designed to allow them to fit into most modern farmyard buildings, making them an extremely manoeuvrable machine.

- Air brakes

Optional Extras

- Two side discharge doors located at both the front and rear of the machine

- Font mounted discharge conveyors

- Elevator extensions for front discharge conveyors which helps to achieve additional discharge height

- Magnet kit to capture steel debris

- Viewing camera with screen in tractor cab for improved visibility

- Wide Angle PTO

FARM COMPARE USER REWARDS- WITH EVERY ENQUIRY:

* Receive a complimentary review from the InTouch and KEENAN technical advisors.

WITH EVERY PURCHASE:

* (NI & ROI & GB) 1 free service.

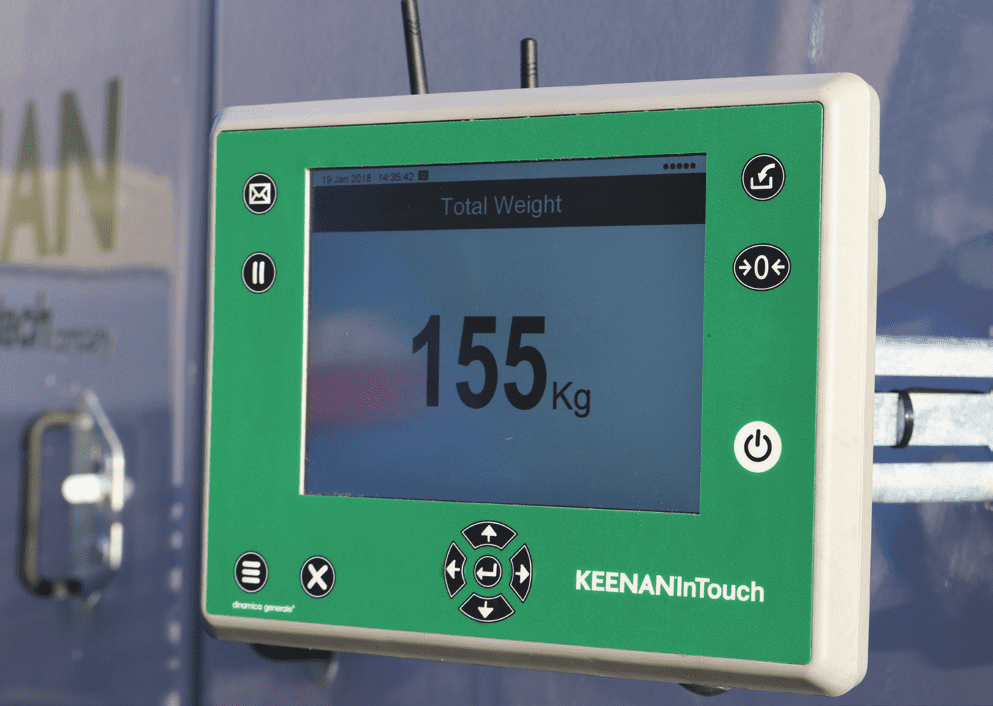

* (NI & ROI) 1-year free subscription to the InTouch feed management technology.

* (NI & ROI) 2 free visits from your regional InTouch feeding specialist.

* (GB) An exclusive KEENAN Driver Pack which includes; winter jacket, set of coveralls, beanie hat, insulated mug and Britains® MechFiber 365 1:32 replica model.

*First time KEENAN users can gain €24,400 in their first year

KEENAN offer a combination of technology and advisory nutrition support to drive feed efficiency and utilisation on farm. According to the IFAC survey only 32% of farms are currently using technology to increase farm efficiencies with 52% mentioning cost as a barrier. With all investment there needs to be a return of investment and first-time users of KEENAN technology increased their feed efficiency by 11% through increased productivity and reduced feed costs, resulting in an extra €244 per cow per year – €24,400 for a herd of 100 cows. More info here

Specification for KEENAN VA 2- 30

Leave a Review

Every KEENAN machine around the world is made in our purpose built factory in Borris, County Carlow, Ireland

Feed efficiency is a very simple concept. It measures how well cows actually use the ration, and it is expressed as the litres produced per kg dry matter intake.

Compare a cow to a car. To assess how efficiently a car performs, the best measure is the miles per litre. More efficient cars go further per litre.

The same is true for cows. Instead of miles think litres, and instead of fuel, think feed. In the same way that a more efficient car will do more miles per litre, so a more efficient cow will produce more milk per unit of feed input.

With feed efficiency, what we are interested in measuring is the litres of milk produced per kgDMI, as a measure of how well the cow is using the ration and how economically they are performing. The principles apply equally when cows are housed and when they are grazing.

The beauty is that Feed Efficiency is a very easy figure to calculate as long as you know how many litres you are producing per day and how many kgDM are being fed, and these figures should be readily available. For example if the average yield per cow (Litres/cow/day) is 27 and the total dry matter fed (Kg/cow/day) is 20.25 then the feed efficiency (kg milk per kg DM) is 1.33

We pride ourselves on our precision built diet feeders, made in our factory in Borris, Carlow by our skilled welders and fabricators. As well as new machines, we have a small range of Approved Used diet feeders available.

A KEENAN diet feeder gives the optimal physical mix in an accurate and consistent manner every day. The KEENAN controller gives the farmer an unprecedented degree of control over a ration’s formulation, its ingredients and its mixing. The KEENAN Controller provides users with guidance on the order of loading and mixing, and the number of paddle revolutions required to get the optimal physical mix.

For ruminant animals, inconsistent and under or over mixing can impact negatively on milk yields and herd health. Under mixed and there will be sorting at the feed fence and a poor mix of long and short feed particles in the rumen. This will result in poor utilisation of the more nutritionally valuable components of the ration.

Over mixing of the ration results in small particles and fibres which promotes the rapid production of acids which can lead to a steep fall in rumen pH and a resulting acidosis. In both situations the rumen is not performing at its optimum and as a result milk yields will fall, feed will not be digested as well and cow health is at risk.

The KEENAN mixer wagon with the KEENAN Controller produces accurately mixed rations time after time, day after day, year after year. It intelligently removes the risk of ration variability.

Whilst our machines are highly reliable we do pride ourselves on having 24/7 breakdown cover from our team of field service engineers located across the country. We aim to ensure a KEENAN customer never misses a feed!

Ask a Question

-

Description

The KEENAN VA2-30 Diet Feeder is a heavy-duty machine with the capacity to feed large herds quickly. Multiple feed-out options to suit a variety of feeding situations are available with this machine. This applies to the full range of the KEENAN VA machines.

Key Features

- Discharge: Front right hand side and rear left and side discharge with trays for dual feedout

- Speed: Engineered to optimise use of space, by allowing materials to be rapidly and efficiently mixed into the overall mixed ration.

- Capacity: The efficient use of space means that this machine may load and mix the full volumes of material consistent with their declared capacity.

- Heavy Duty Auger and Blades: Fitted with a heavy duty auger as standard. The triangular blades are fitted with a long lasting tungsten coating which increases their longevity. The additional two blades are fitted towards the top of each auger ensuring rapid incorporation of bales.

- Inspection platform: Fitted as standard this machine offers an inspection platform for viewing the mix.

- Heavy Duty Chassis: This machine is mounted on a custom-built heavy duty chassis. Its robust construction ensures durability and reliability even under the toughest conditions.

- Hay Ring: This machine is fitted with a hay ring to prevent overflow of material.

- Footprint and Handling: This machines footprint is designed to allow them to fit into most modern farmyard buildings, making them an extremely manoeuvrable machine.

- Air brakes

Optional Extras

- Two side discharge doors located at both the front and rear of the machine

- Font mounted discharge conveyors

- Elevator extensions for front discharge conveyors which helps to achieve additional discharge height

- Magnet kit to capture steel debris

- Viewing camera with screen in tractor cab for improved visibility

- Wide Angle PTO

FARM COMPARE USER REWARDS- WITH EVERY ENQUIRY:

* Receive a complimentary review from the InTouch and KEENAN technical advisors.WITH EVERY PURCHASE:

* (NI & ROI & GB) 1 free service.

* (NI & ROI) 1-year free subscription to the InTouch feed management technology.

* (NI & ROI) 2 free visits from your regional InTouch feeding specialist.

* (GB) An exclusive KEENAN Driver Pack which includes; winter jacket, set of coveralls, beanie hat, insulated mug and Britains® MechFiber 365 1:32 replica model.*First time KEENAN users can gain €24,400 in their first year

KEENAN offer a combination of technology and advisory nutrition support to drive feed efficiency and utilisation on farm. According to the IFAC survey only 32% of farms are currently using technology to increase farm efficiencies with 52% mentioning cost as a barrier. With all investment there needs to be a return of investment and first-time users of KEENAN technology increased their feed efficiency by 11% through increased productivity and reduced feed costs, resulting in an extra €244 per cow per year – €24,400 for a herd of 100 cows. More info here -

Specifications

3340mm 2700mm 8200mm 30m3 225-240 450-480 Passage Trough Vertical Large Farm Dairy Beef Sheep N/A 104-140 -

Reviews

This product has no reviews.Leave a Review

-

Q&A's

Question: I have a dead end feed passage how can I feed out? Answer:We have the ability to customise each machine with a variety of feed out options. We can fit a rear feed out conveyor which has the ability to feed out on two sides simultaneously at the rear of the machine. We have solutions for each application.

Question: Where are Keenan machines made? Answer:Every KEENAN machine around the world is made in our purpose built factory in Borris, County Carlow, Ireland

Question: What is feed conversion efficiency? Answer:Feed efficiency is a very simple concept. It measures how well cows actually use the ration, and it is expressed as the litres produced per kg dry matter intake.

Compare a cow to a car. To assess how efficiently a car performs, the best measure is the miles per litre. More efficient cars go further per litre.

The same is true for cows. Instead of miles think litres, and instead of fuel, think feed. In the same way that a more efficient car will do more miles per litre, so a more efficient cow will produce more milk per unit of feed input.

With feed efficiency, what we are interested in measuring is the litres of milk produced per kgDMI, as a measure of how well the cow is using the ration and how economically they are performing. The principles apply equally when cows are housed and when they are grazing.

Question: How do you calculate feed conversion efficiency? Answer:The beauty is that Feed Efficiency is a very easy figure to calculate as long as you know how many litres you are producing per day and how many kgDM are being fed, and these figures should be readily available. For example if the average yield per cow (Litres/cow/day) is 27 and the total dry matter fed (Kg/cow/day) is 20.25 then the feed efficiency (kg milk per kg DM) is 1.33

Question: Do you only sell new feeders? Answer:We pride ourselves on our precision built diet feeders, made in our factory in Borris, Carlow by our skilled welders and fabricators. As well as new machines, we have a small range of Approved Used diet feeders available.

Question: Why choose a KEENAN machine? Answer:A KEENAN diet feeder gives the optimal physical mix in an accurate and consistent manner every day. The KEENAN controller gives the farmer an unprecedented degree of control over a ration’s formulation, its ingredients and its mixing. The KEENAN Controller provides users with guidance on the order of loading and mixing, and the number of paddle revolutions required to get the optimal physical mix.

Question: Does the physical mix matter? Answer:For ruminant animals, inconsistent and under or over mixing can impact negatively on milk yields and herd health. Under mixed and there will be sorting at the feed fence and a poor mix of long and short feed particles in the rumen. This will result in poor utilisation of the more nutritionally valuable components of the ration.

Over mixing of the ration results in small particles and fibres which promotes the rapid production of acids which can lead to a steep fall in rumen pH and a resulting acidosis. In both situations the rumen is not performing at its optimum and as a result milk yields will fall, feed will not be digested as well and cow health is at risk.

The KEENAN mixer wagon with the KEENAN Controller produces accurately mixed rations time after time, day after day, year after year. It intelligently removes the risk of ration variability.

Question: Do you have service engineers or breakdown cover? Answer:Whilst our machines are highly reliable we do pride ourselves on having 24/7 breakdown cover from our team of field service engineers located across the country. We aim to ensure a KEENAN customer never misses a feed!

Ask a Question

-

Attachments

-

Images

-

Videos

We have the ability to customise each machine with a variety of feed out options. We can fit a rear feed out conveyor which has the ability to feed out on two sides simultaneously at the rear of the machine. We have solutions for each application.